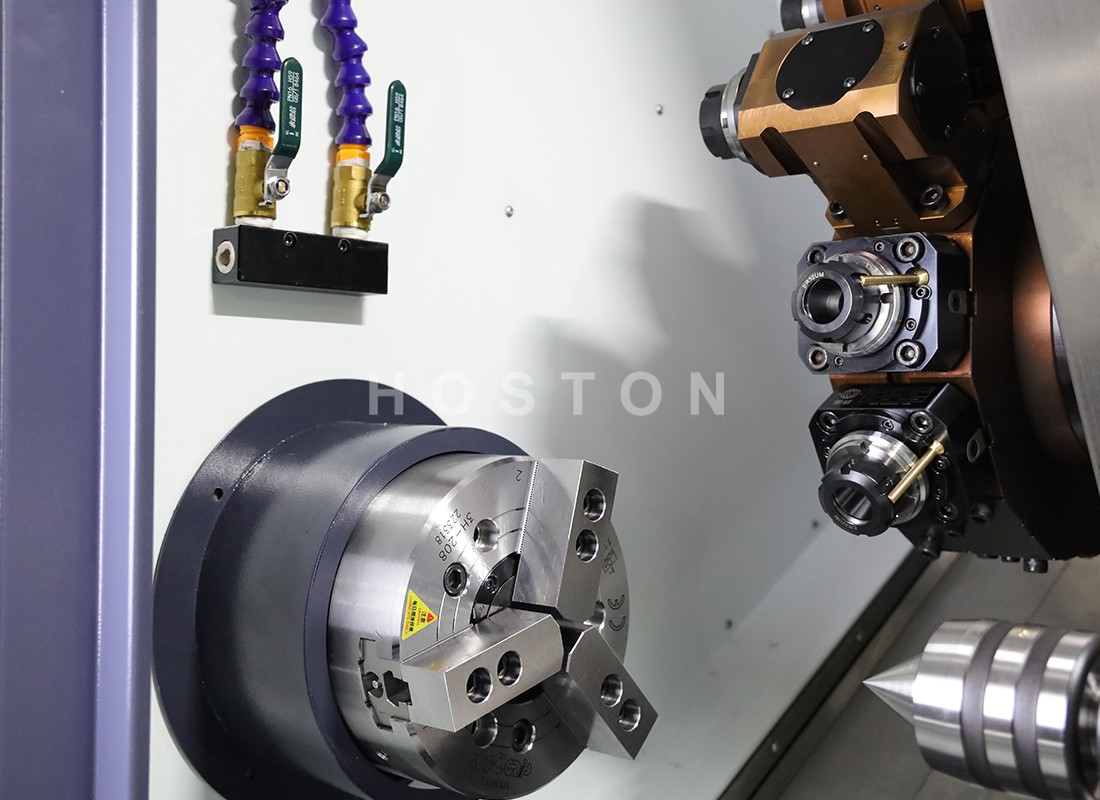

CNC Lathe are mainly used for inner and outer outer circular surfaces of shaft parts or disk parts, inner and outer conical surfaces of arbitrary taper angles, complex inner and outer surfaces rotating and cylindrical, conical threads and other cutting processes, And can carry out grooving, drilling, reaming, reaming. Today we mainly talk about how to reduce the thermal deformation of the CNC lathe spindle.

1. Reduce the heat source, focus on adjusting the spindle bearing speed, clearance and reasonable preload. For thrust bearings and tapered roller bearings, due to their poor working conditions and high heat generation, if necessary, thrust angular contact ball bearings can be used instead to minimize the frictional heat generation of some parts.

2. Heat insulation, keep the heat source away from the main shaft, such as motor, transmission isolation, separation transmission, etc.

3. Heat dissipation, strengthen lubrication cooling, oil cooling, air cooling and other methods to speed up heat dissipation.

4. In order to reduce the influence of thermal deformation, no matter what method is used, it can only reduce thermal deformation, and it is difficult to completely eliminate thermal deformation. Therefore, measures should be taken to reduce the effects of thermal deformation.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: